Mud Gas Separator

What is Mud Gas Separator?

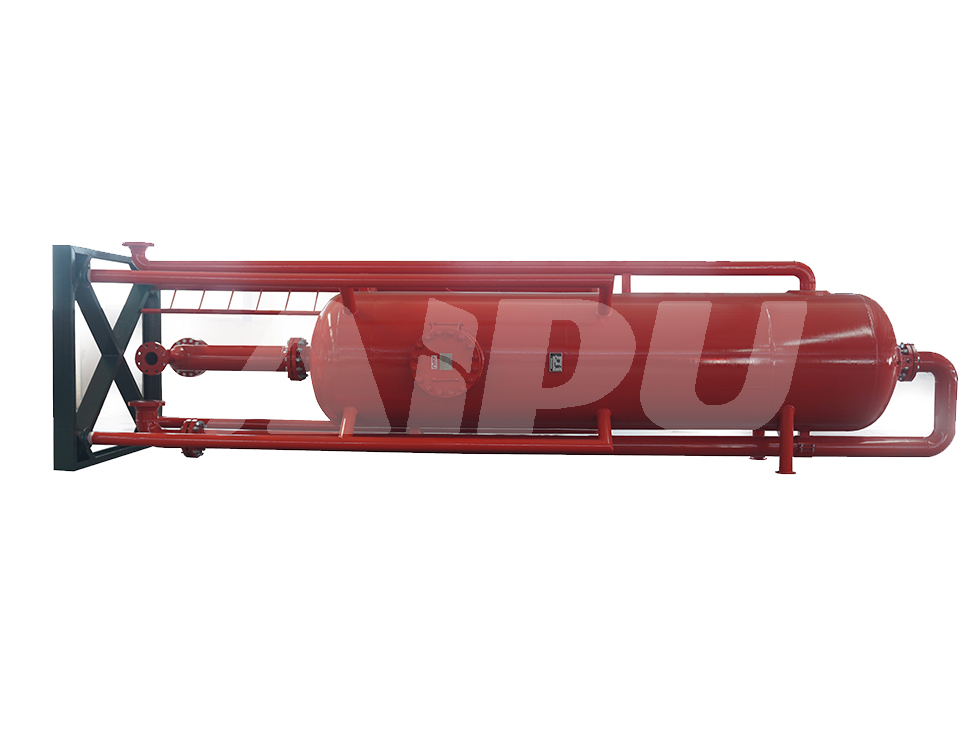

Poor boy degasser is a equipment to treat the gas invade mud. If there is a "KICK" situation, this vessel separates the mud and the gas by allowing it to flow over baffle plates. The gas then is forced to flow through a line and vent it to a flare ignition device.

Product Description

Poor boy degasser is a equipment to treat the gas invade mud. If there is a "KICK" situation, this vessel separates the mud and the gas by allowing it to flow over baffle plates. The gas then is forced to flow through a line and vent it to a flare ignition device. Considering safe operation, the vent line should be at least 60 m. Some clients even request 100m. For oil and gas well drilling, we usually set mud gas separator ahead of shale shakers.

Application Effects and Advantages

- Common carbon steel or H2S resistant steel for option

- Heavy-duty marine anti-corrosion painting with 3 layers

- Unique design ensures constant liquid level in the separator and solves the problem of sand accumulation inside the tank

- The combination of multiple separation technologies such as centrifugal separation, physical impact separation, and vacuum separation ensures the separation effect of gases

- Buffer devices are installed at the corners of the liquid supply pipe and replaceable impact resistant baffles are added. Regular inspection and replacement can be carried out according to wear conditions to extend the service life

- The sulfur resistant mud gas separator is manufactured and processed entirely with special materials, which can completely prevent damage to the equipment caused by hydrogen sulfide in the gas.

Specifications and Parameters

| Model | APMGS800 | APMGS1000 | APMGS1200 | APMGS1400 |

|---|---|---|---|---|

| Vessel Dia. | 32" | 40" | 48" | 52" |

| Capacity | 200~260m³/h | 240~300m³/h | 280~360m³/h | 320~420m³/h |

| Inlet Dia. | 5" | 5" | 5" | 5" |

| Discharge Line Dia. | 8" | 8" | 10" | 12" |

| Vent Line | 8" | 8" | 8" | 8" |

More Options

Customizable Options for APMGS Mud Gas Separator

Facing the international market, based on the actual needs of users, AIPU provides flexible configuration for customers. The following are the main optional parameters:

- Pressure Requirements – Customized

- Material – Common carbon steel or H₂S resistant steel for option

- Certification & Inspection – Pressure vessel, inspection certification and etc.

- Surface Color

Why Choose Aipu Solid Control?

As the top solid control manufacturer in China, Aipu Solid Control always puts customer needs first. We firmly believe that technology can create the future, but service is the bridge that turns technical strength into real value for customers. Aipu Control insists on providing high-quality products and services. And it is an honor to be your ideal global supplier of drilling fluid treatment equipment. Looking forward to serving you.

Our Commitment

We are committed to delivering:

- High-quality, reliable equipment

- Competitive pricing

- Responsive technical support

- Customized solutions

- Timely delivery

Request a Quotation

Please provide your details and we'll get back to you soon with the best solution for your needs.